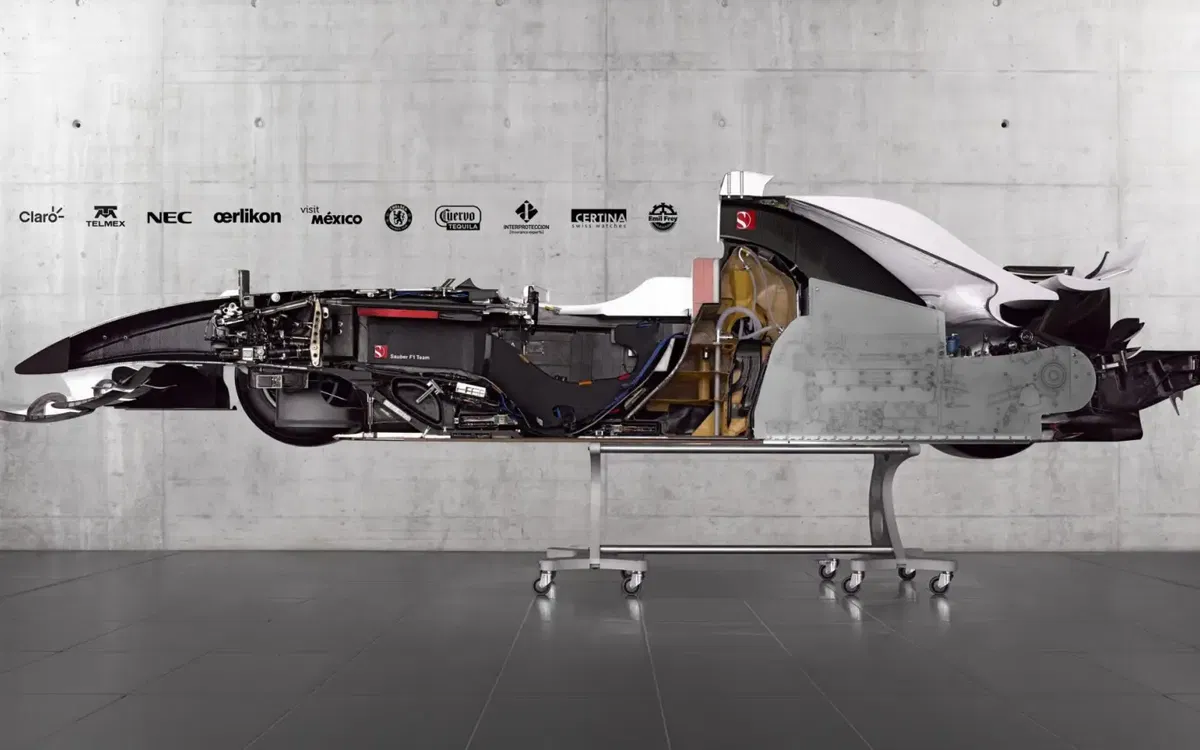

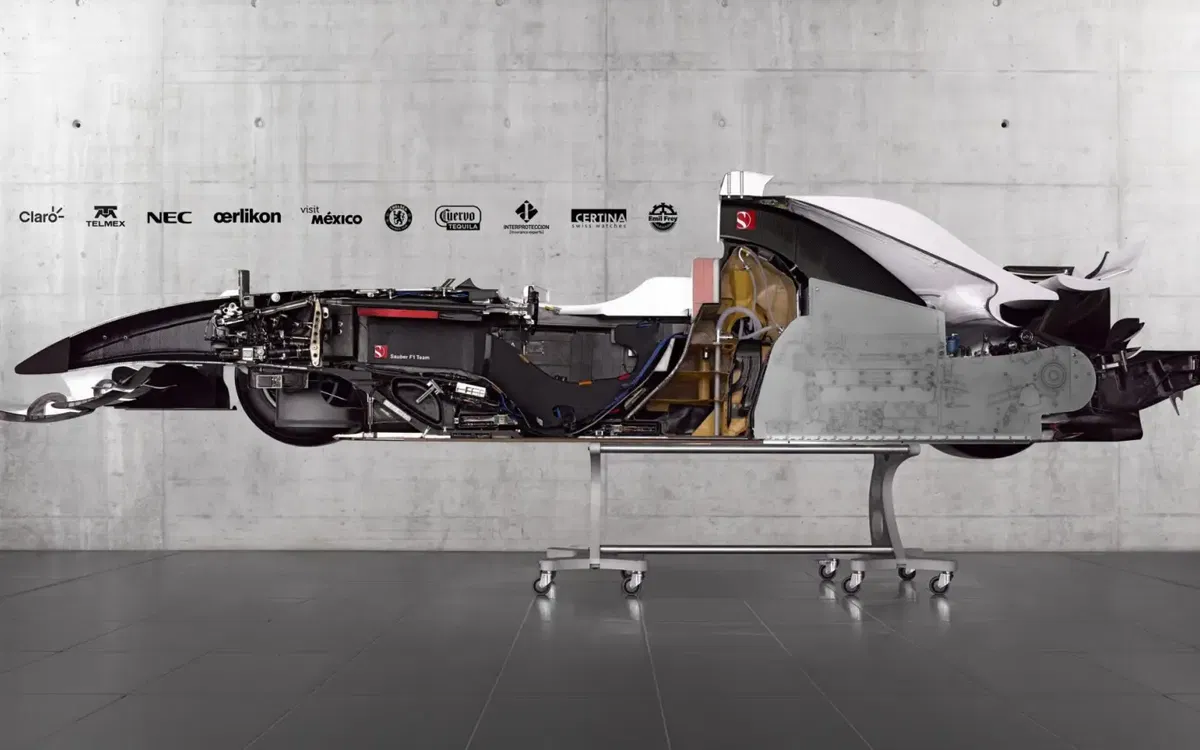

Performance is always at the front and center for a Formula 1 team when they’re building a new car. And while technical aspects like the Power Unit, Suspension geometry, Aerodynamics, etc, have a direct impact on the performance, there’s one crucial element concerning the drivers that’s often overlooked. I am talking about the race seat. A Formula 1 car’s seat is a crucial component that plays a vital role in ensuring the driver’s safety, comfort, and performance. Since drivers experience extreme forces during races, achieving the perfect seat fit is essential for them to feel at one with the car and extract maximum performance.

Watch What’s Trending Now!

While we often catch glimpses of drivers settling into their cockpits through released photos and videos, the intricate process behind the scenes remains largely unseen. For drivers, the seat fit holds utmost importance as it directly influences their connection to the car. In a sport where every millimeter counts when you’re facing forces greater than five times that of gravity, an ill-fitting seat can delay a driver’s reaction to changes in forces on the car, impacting their performance on the track.

ADVERTISEMENT

Everything you need to know about how F1 race seats are made

In the early days of F1, seat fitting was a rudimentary affair involving drivers sitting in chassis with expanding foam poured around them. The process was far from perfect, with foam mishaps leaving drivers in difficult situations. However, as technology advanced, so did the methods of seat fitting. Today, seat fitting involves intricate carbon shells tailored precisely to each driver’s measurements. These shells not only ensure a snug fit but also prioritize safety, with regulations mandating a minimum distance between the seat back and the chassis front bulkhead to protect drivers in the event of a crash.

Essentially, making the seat of a Formula 1 car isn’t a one-step process. It involves the following multiple stages.

Top Stories

Who Is Oscar Piastri’s Father, Chris Piastri? Co-Founder of Multibillion Dollar Automotive Company

3 Years After His Death, Niki Lauda’s Wife Brutally Disrespects Him to Initiate $32,000,000 Battle Against Own Children

Language Barrier Didn’t Hold Back Lando Norris to “Hook Up” With OnlyFans Model: “We Talked by Mime”

Who is Ayumu Iwasa? The Red Bull Junior Team Driver from Japan

Are Max Verstappen’s Parents Separated? Everything to Know About His Difficult Childhood

ADVERTISEMENT

Stage 1 – Molding of the seat

The first step in achieving the ideal fit is for the drivers to wear their complete racing gear and settle into a mold of the cockpit. This mold, filled with expanding foam, shapes itself around the contours of their bodies and the inner structure of the chassis. It’s like crafting a custom-made seat tailored to each driver’s unique physique.

#NL6 getting comfy ahead of his rookie season 🪑 pic.twitter.com/3vi80nYHFD

— Williams Racing (@WilliamsRacing) February 14, 2020

ADVERTISEMENT

Stage 2 – Comfort Testing

Comfort is crucial in the pursuit of the perfect fit. Drivers simulate their movements during racing to ensure that their arms and elbows feel just right as the foam expands around them. Some drivers prefer to feel almost ‘stuck’ in the car, minimizing head, neck, and shoulder movements for consistent perception during high-speed maneuvers.

ADVERTISEMENT

Stage 3 – Digital Modeling

Once the foam mold is formed, it’s digitally scanned to create a 3D model, which serves as the basis for crafting the final carbon fiber seat. This seat is then meticulously adjusted to meet the driver’s specifications, ensuring everything from pedal reach to steering wheel rotation is optimized for performance and safety. Gaps or cavities are intentionally left under the seat for comfort padding to be added later.

3D Printed RedBull RB16 F1 Update: Laying up the seat in Carbon Fiber and vacuum bagging. This was an intense step and it's not over yet, but it'll be exciting when we pop it from the mold. #mystudentsrock #F1 #formula1 #redbull #redbullracing #simulator #fullsailuniversity pic.twitter.com/DgUJzKeC0Q

— Pat Starace (@patstarace) January 27, 2023

ADVERTISEMENT

Stage 4 – Carbon Fiber Seat Production

Layers of carbon fiber are applied to the mold and cured in an autoclave (a pressurized oven) to create the final carbon fiber seat. Openings are cut into the seat for safety devices like seatbelts and the HANS (Head and Neck Support) device. The driver then sits in the carbon fiber seat inside the cockpit, and any necessary adjustments are made based on their feedback. The seat can be optimized to meet the driver’s requirements.

HANS device has been mandatory in F1 since 2003. The Head And Neck Support, goes between the seat belts and drivers shoulders with straps connecting to the helmet.

This one is JB's from his Brawn days, currently up for auction.https://t.co/2d5ORQm9bH pic.twitter.com/RMjx4r0BlG— Craig Scarborough (@ScarbsTech) August 25, 2021

ADVERTISEMENT

Stage 5 – Ergonomic Considerations

Beyond just the seat, attention is paid to every small detail of the driver’s cockpit, from the positioning of the steering wheel to the placement of the pedals. These factors directly impact a driver’s ability to operate the car smoothly and efficiently. Even seemingly minor issues, like pedal placement or headrest positioning, can have significant consequences on the track. And so, the driver’s position in the cockpit must comply with safety regulations regarding height and visibility.

ADVERTISEMENT

Stage 6 – Padding and Heat Protection

While safety and performance considerations are extremely important when making a Formula 1 seat, they aren’t the only crucial factors. Driver comfort plays a big part as well. Padding can be added for extra comfort, although every addition is carefully considered to minimize added weight. For that extra touch, a layer of gold foil is applied to the seat to reflect infrared rays and shield the driver from the intense heat generated by the powertrain behind them.

ADVERTISEMENT

Stage 7 – Track Testing

The true test of a successful seat fit comes when the driver hits the track with their newly fitted seats. Only then can they provide feedback on the seat’s performance. Minor adjustments can be made if needed, but if significant changes are required, the whole process starts again to ensure the perfect fit is achieved.

Some other important aspects of a Formula 1 racing seat

It’s important to note that while the seat’s primary function is to maintain the driver’s position, it also accommodates a degree of adjustability. Mounting points at the front and rear facilitate height and tilt adjustments, enabling drivers to fine-tune their seating position according to personal preference and track characteristics. On circuits like Monaco, where visibility takes precedence over pure performance, drivers may opt for a slightly elevated seating position, sacrificing the low center of gravity that typically provides a handling advantage.

Remarkably, the seat itself is not permanently fixed to the cockpit. Instead, it slots into a series of pins or mounts, a design choice that prioritizes rapid extraction in the event of an accident. The anchoring force that secures the driver is not the seat itself but rather the seat belts, which work in combination to hold the driver firmly in place, even under the extreme forces experienced during high-speed cornering and braking.

READ MORE: About Cockpits in F1 Including Dimensions, Halo & Others

What are your thoughts on the nuanced process of making modern-day Formula 1 seats? Feel free to start a conversation in the comments down below.

ADVERTISEMENT

ADVERTISEMENT

ADVERTISEMENT